| natural gas, coke oven gas, blast furnace gas, crude oils, refined products, lubricating oil, NGL & LPG. | هیدروکربن ها – Hydrocarbons |

| air, nitrogen, oxygen, argon, hydrogen, carbon-dioxide, carbon-monoxide, propane, ethylene, ammonium, general gases.. | گازهای صنعتی – Industrial gases |

| ethanol, MTBE, ETBE, general liquids, liquid mixture. | سیالات مایع – Liquids other than water |

| Water, water steam, water-glycol mixture – energy flow (heat transfer) calculation. | آب – Water |

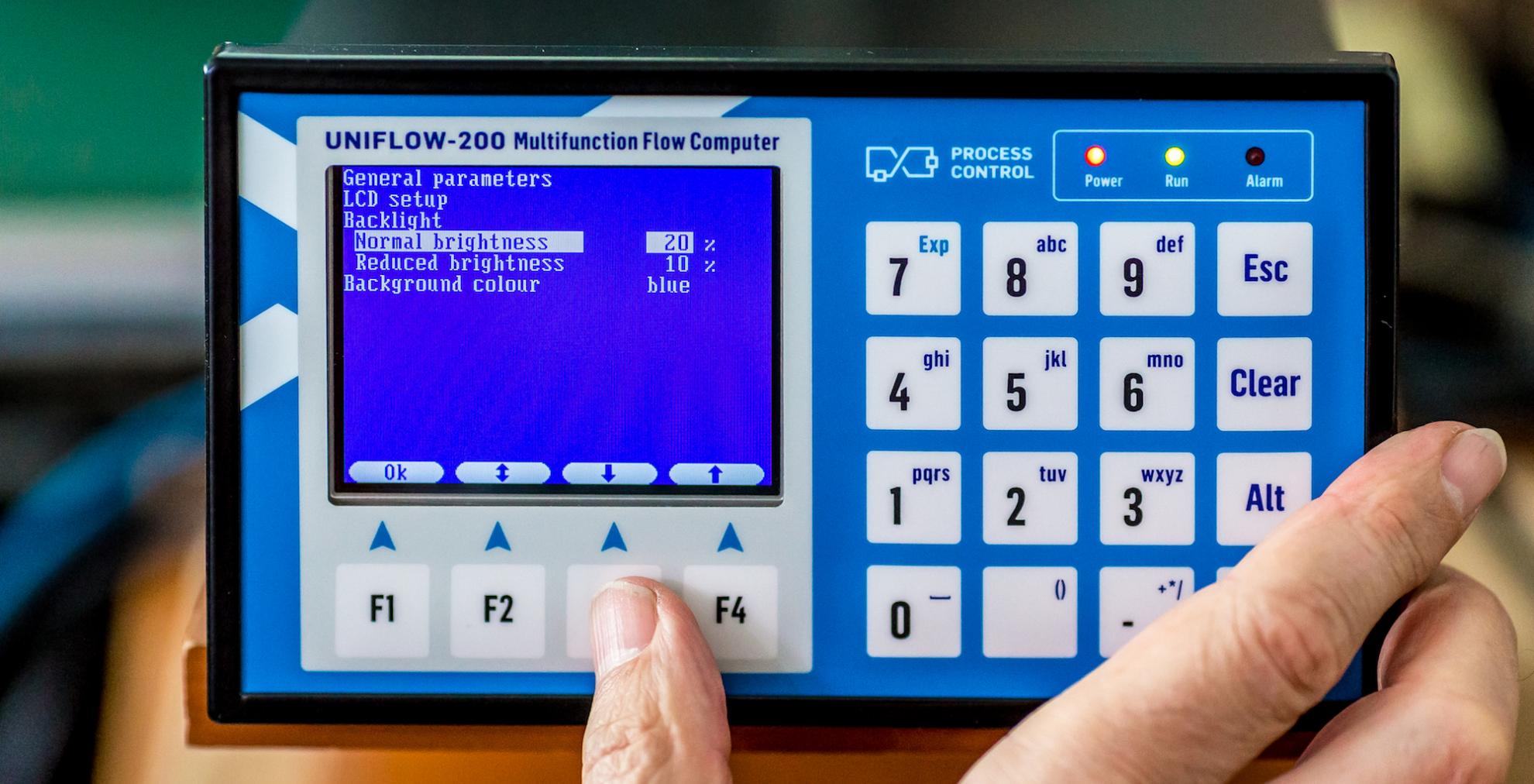

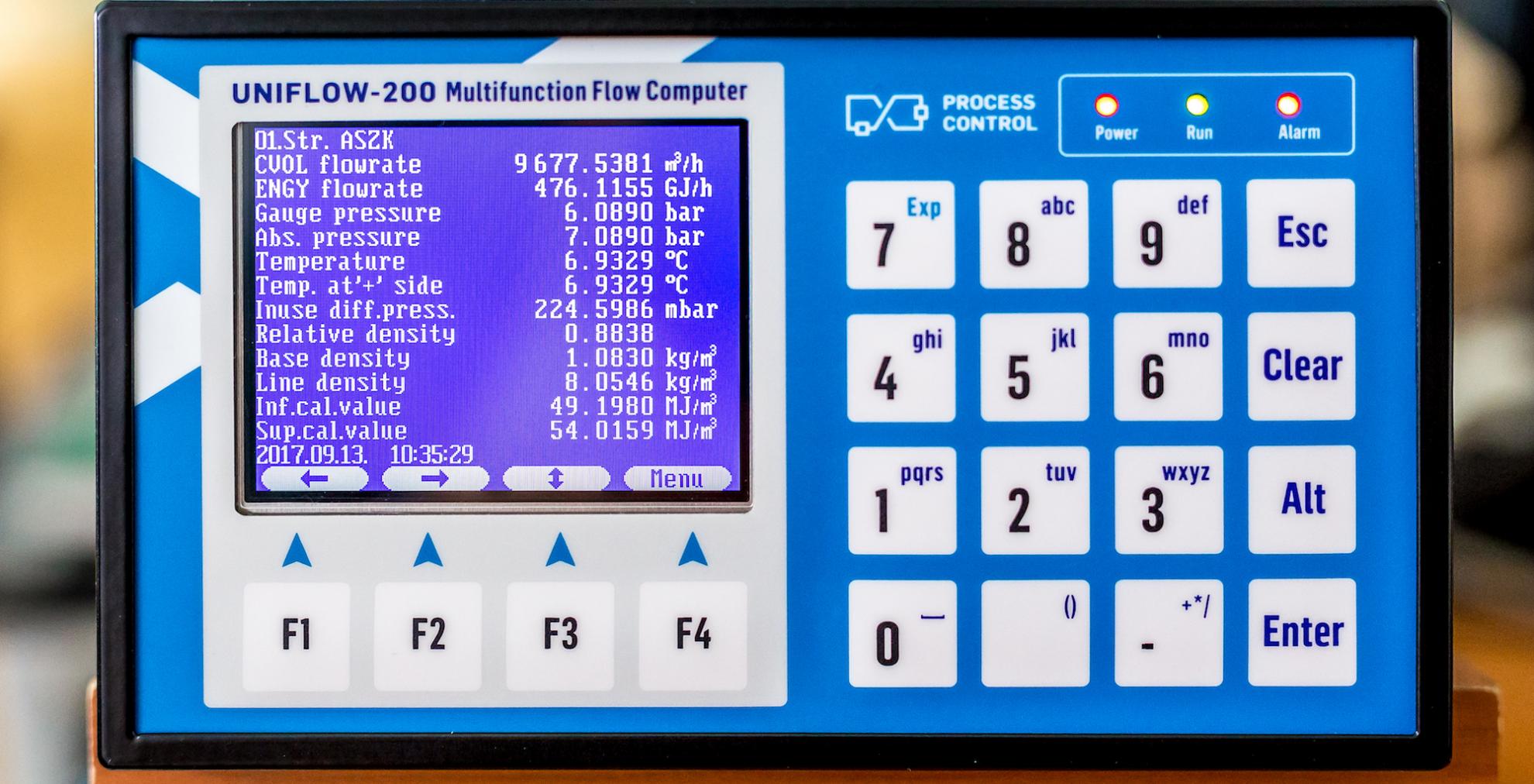

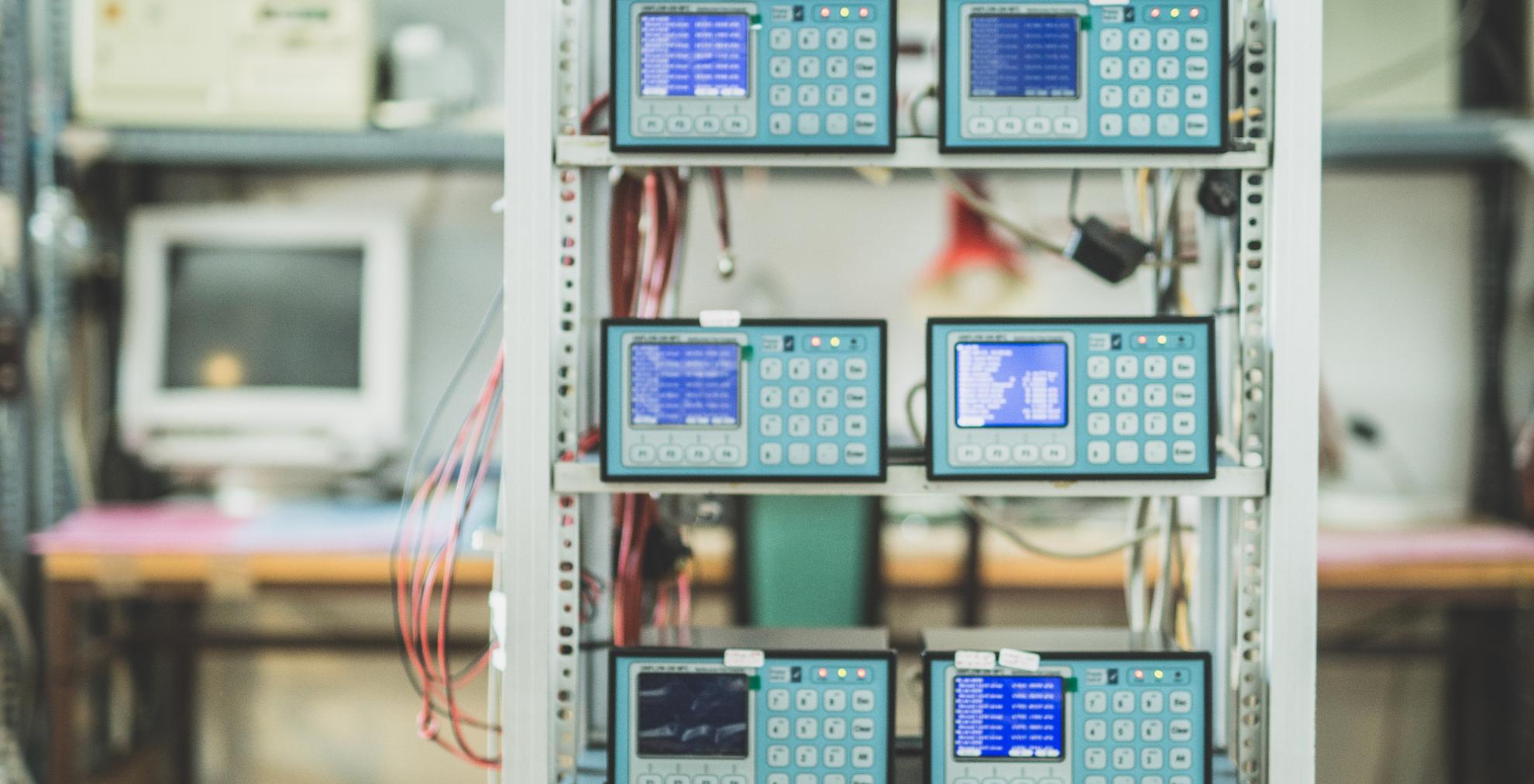

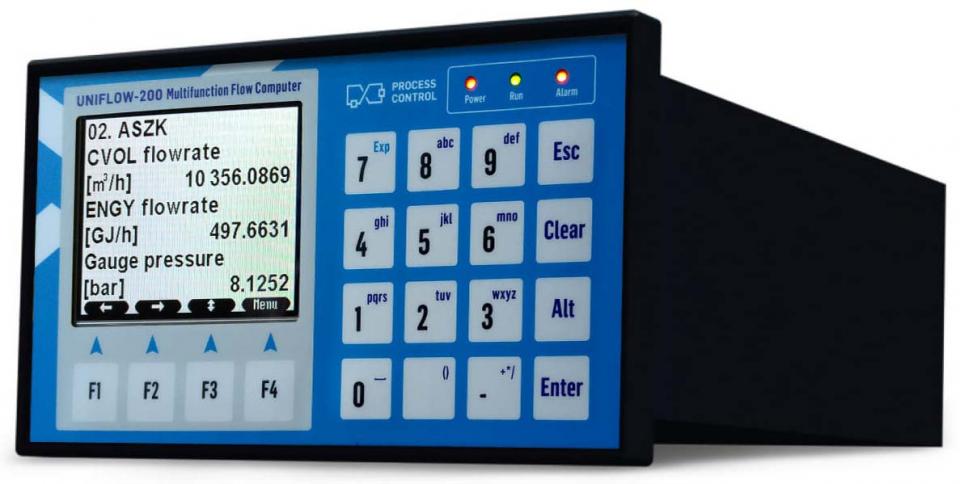

UNIFLOW-200 MULTIFUNCTIONAL FLOW COMPUTER

فلوکامپیوتر مولتی فانکشن Uniflow 200 یکی از انعطاف پذیر ترین فلوکامپیوتر های موجود در دنیا میباشد. بستری ایده آل برای پیچیده ترین کاربردها در زمینه اندازه گیری فلوی عبوری! هر سیالی یا هرنوع فلومتری!

Advantages

- UNIVERSAL – Works with all fluids & flow meters, supports all standards.

- RELIABLE – Extremely robust & reliable, 3 years full warranty.

- MODULAR – Multi-run and multi-station design, ideal for any application.

- AFFORDABLE – Flow meter costs as low per meter run.

- USER-FRIENDL – Easy to use & maintain, no training required.

- TOP-NOTCH SUPPORT – Personal attention & exceptional customer care included.